Lithography

Lithography is the most efficient process to produce bulk print work at the best possible quality. Using etched plates with smooth surfaces, lithography imprints images and text onto sheets with exact precision. With a large range of inks available, lithography can print in any pantone colour or in four colour process. This allows repeat jobs to be printed exactly the same as previous ones. Lithography is most popular on most printed stationery as it can be printed in exact colour’s, matching company logos and colour’s on all their printed stationery. Lithography is more expensive than digital print on smaller runs but unlike digital print, larger runs would be more cost effective as a lot of the cost is in the set up, so runs of higher quantities can bring unit costs down significantly.

Lithographic print

Digital

Modern printing methods such as laser and ink-jet printing are known as digital printing. In digital printing, an image is sent directly to the printer using digital files such as PDFs and those from graphics software such as Illustrator and InDesign. This eliminates the need for a printing plate, which is used in Litho offset printing, which can save money and time.

Without the need to create a plate, digital printing has brought about fast turnaround times and printing on demand. Instead of having to print large, pre-determined runs, requests can be made for as little as one print. While offset printing still often results in slightly better quality prints, digital methods are being worked on at a fast rate to improve quality and lower costs.

Digital Print

Foil Blocking

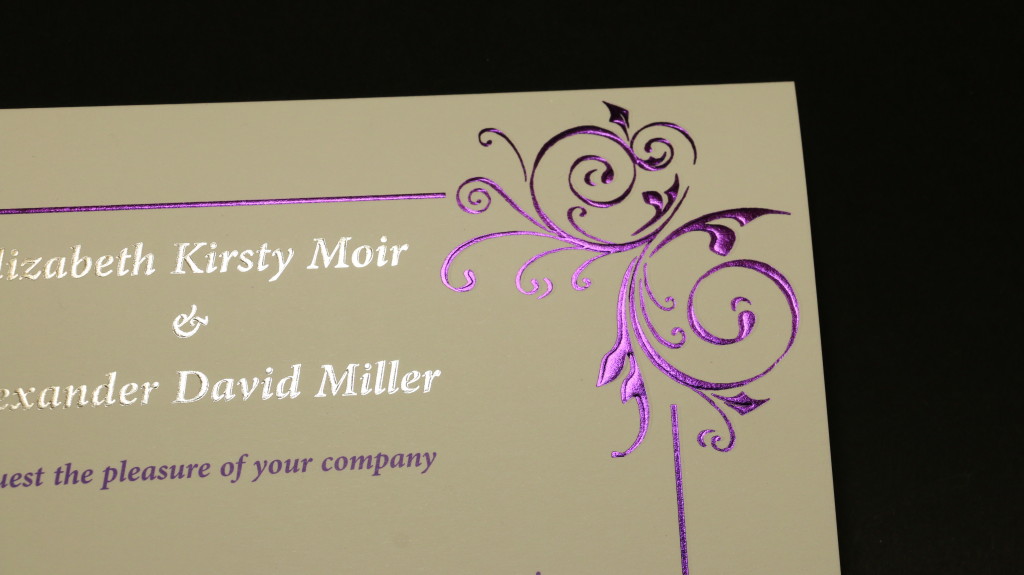

Foil blocking, is the application of a silver, gold or coloured foil. This technique can help you to create much more special and unique designs, than you could have with regular inks.

It can enhance the look of any printed product from Business cards to Fashion catalogues and you can get creative with it. Its uses a metal die which is super-heated and then impressed onto the card or paper to leave only the etched design foiled into the card. You can enhance even further by blind embossing to give a raised 3d effect.

Silver and Purple foil

Letterpress

Starting in the 15th century, letterpress has been the regular printing technique until the 19th century. The process of letterpress printing demands much more work than modern techniques, the printer needs to compose and lock movable type into the bed of a press, ( or you can get metal and plastic plates etched to do a similar job), then ink it and press it into the card or paper.

It is a set of skills that not all workers can achieve properly nowadays ( we can of course ! ) but it can give beautiful results.

When using wooden blocks for printing, usually chosen for larger formats like posters, the ink will often have a nice texture that gives it a handmade feeling. With metal letters, you will get a slight debossing in your paper that gives some depth to your design. In both cases, the craftmanship that is necessary for printing will be visible on the final outcome, especially if you use some of the vast choice of papers.

After being discarded to use more modern printing techniques, letterpress has become popular again and is often used by graphic designers for smaller scale print work, such as business cards or wedding invitations.

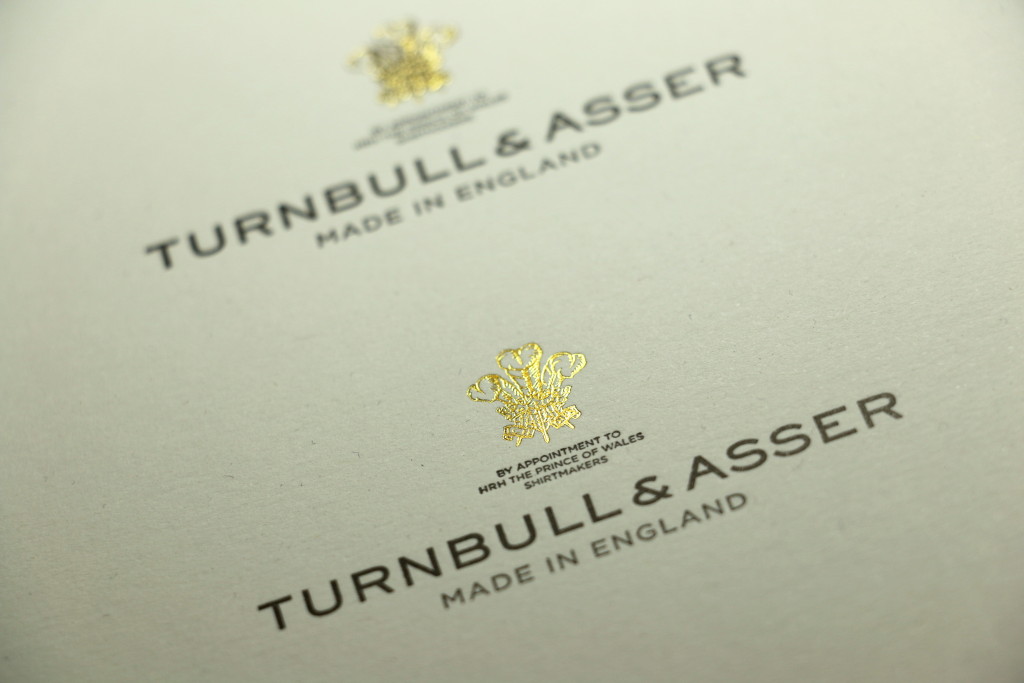

Gold Foil and Letterpress

Thermography

Thermography raises and gives print an added dimension. The freshly printed sheets are coated with powder that adheres to the wet ink which is then passed through a heat tunnel which melts and raises the powdered ink. The end result is raised print. Thermography is a cost effective way to raise print.

For this reason it is a popular solution for business cards and invitations, Letterheads can be thermographed with a laser guaranteed powder.

Thermography

Embossing and Debossing

Embossing, or debossing for the opposite effect (but it uses the same technique), is the process of raising a pattern against the background (while debossing sinks the pattern). This technique creates relief in your printed work and gives it a third dimension.

Embossing can be blind or applied to already printed work to raise or sink the printed image out or into the card or paper. Embossing uses a male and female engraved die.

Debossing does not use a female die and is a similar process to foiling, but without the foil.

Blind Emboss

Die Stamping

Die stamping is a process that elaborates detail with precision which no other printing process can produce.

Die stamping and engraved printing is produced with an engraved copperplate.

The paper or board is traditionally hand fed into a copper-plate printing press, these presses print and emboss at the same time.

This is a fine art process which is still used on Multi colour crests or to add a sensual feel to an Invitation or Business Card.

All our Die Stamping Services are completed by our AP Landragin branch which we have recently acquired. AP Landragin have been providing Die Stamping services to London for over 80 years.

Please click on the link below to read more on AP Landragin Ltd

Die Cutting

Die cutting, while not a printing technique per se, can turn an average design into a beautiful piece of work. Like printing, the process involves a press, but this time for cutting the paper with various shapes. The shapes can be regular or custom-made.

Die cut is often used to give business cards a different shape, but it can be used on pretty much anything: postcards, brochures, catalogue front pages to reveal the next page, book covers, and greeting cards.

Spot UV

Spot UV is when a clear varnish is applied to an already printed image to give the image an extra gloss and feel that will make it stand out. This process is very popular in company brochures, highlighting a specific image or part of the page and on front covers or letterheads to increase the effectiveness of a company name or logo.

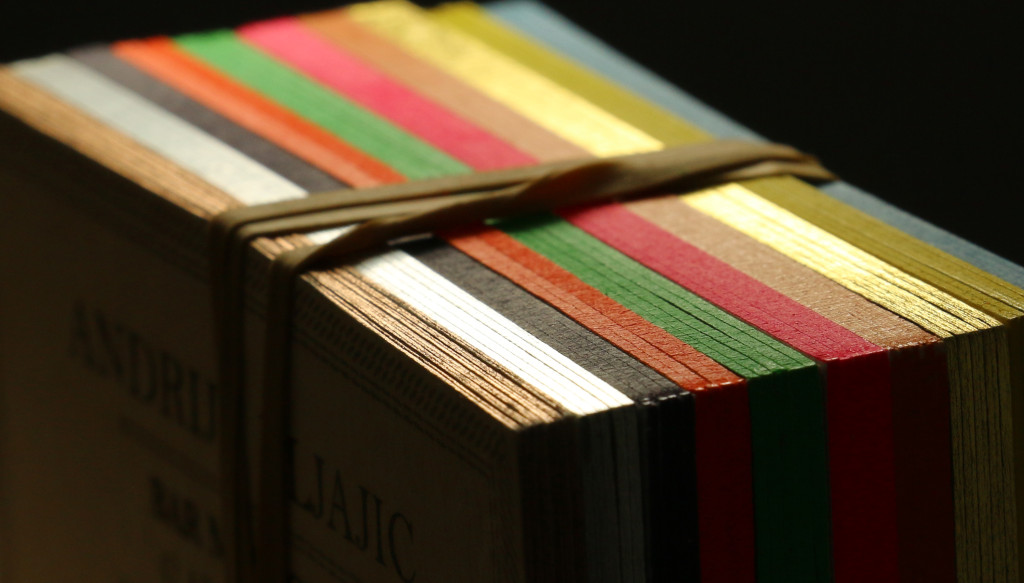

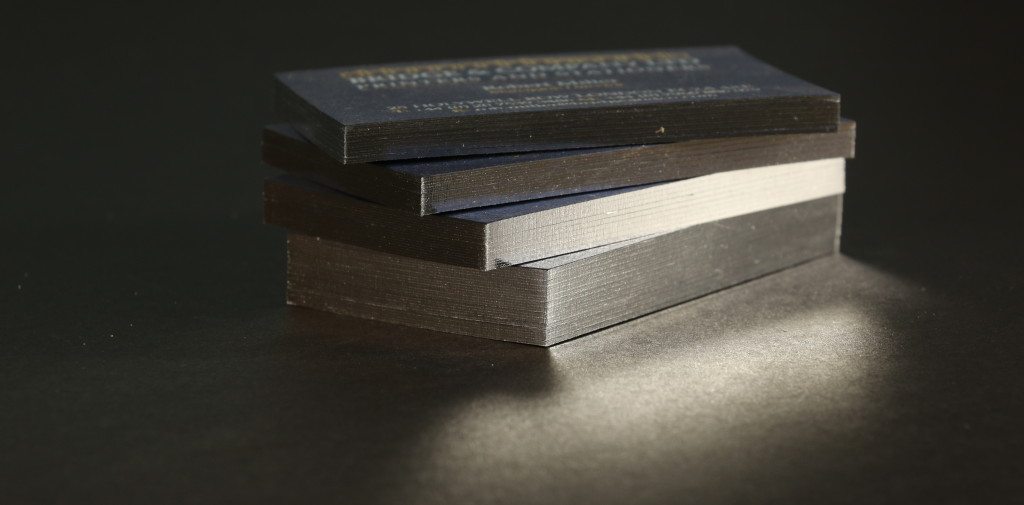

Duplexing

Duplexing or triplexing refers to bonding two or three sheets together to make a thicker finished card. However, the process is not limited to this number of sheets and the possibilities are endless. Different colours, makes and weights of card can be combined to produce impressive finished items.

Invitations and business cards are most popular and benefit most from this process.

Gilding & Pantone edging

Edging is when a gloss or matt foil or ink is applied to the edge of a card or sheet to leave a colour effect. This process is very popular on business cards and invitations and will give your card an extra effect that will make friends and clients look at your card twice.

Gilding or having the cards edged in a matching pantone colour can be the perfect way to enhance the finished look of your printed item.

Coloured Edging

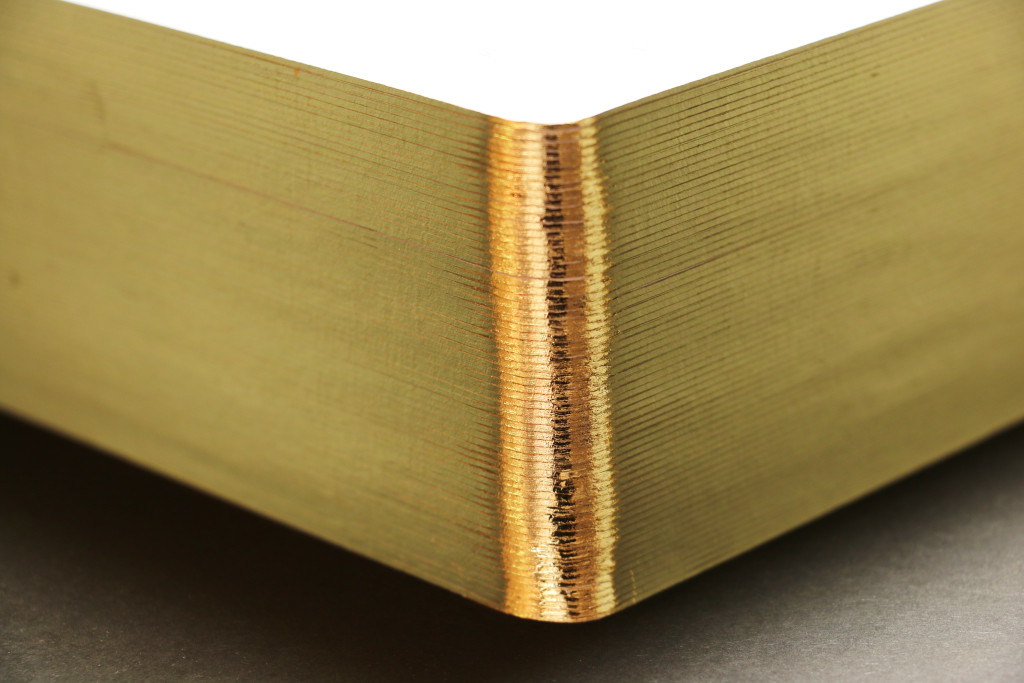

Gilt Edge Cards

Gilt Edged Business Card

Square Edge Gilding